machining surface finish guide

The standard roughness for CNC machined parts is Ra 32 microns but you can do as fine as for example 02 microns on a CNC machine but it might take 10 times longer and. Determining the surface roughness is the first step that should occur after plastic parts are machined.

Why Use A Surface Finish Chart Metal Surface Finish

It is normally identified by the layer of the surface pattern roughness.

. Mainly to make the. In general a surface finish is described as a measure of the texture of a surface. Surface Roughness of Abrasive Grits and Sandpaper.

Make use of a high-resolution probe to gauge the surface. Surface finish is composed of three. Machining lapping is optimal for products requiring precise flatness parallelism with measured requirements in terms of consistency and finish.

Three 3 major characteristics can define the surface finish. Anodizing Type III adds a wear- and corrosion-resistant ceramic layer to the surface of the part. The goal of the machinist is to achieve surface finishes on parts that are as good as those required by the designer but not better as that results in the cheapest to manufacture.

Standard Surface Finishes. Surface Finish Units. It offers greater protection than Type II and can be dyed different colors.

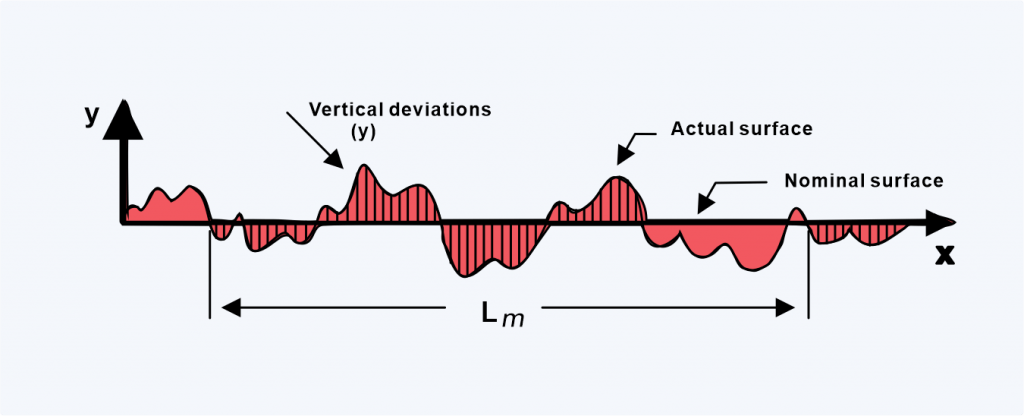

Gauge the finite area as. Surface finish is a measure of the roughness of a surface. It is a means of altering material surfaces through processes involving adding removing or reshaping the metal surface.

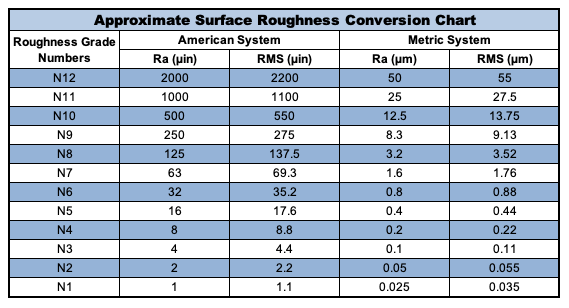

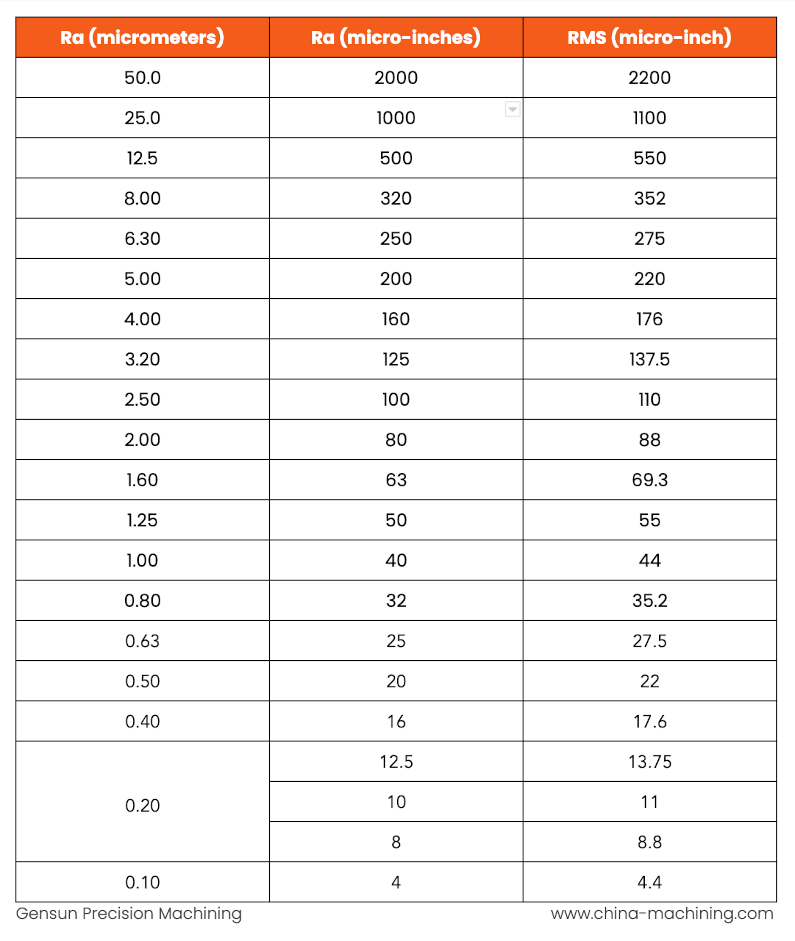

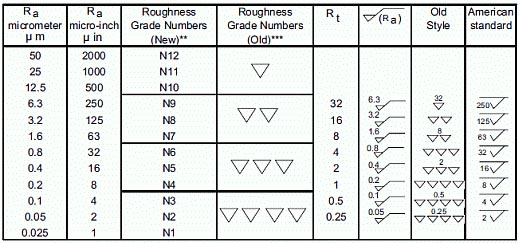

To learn more about surface finishing read our guide to plastic injection molding surface finish options and read our article about getting the best CNC machining surface finish for your. Here is a chart table showing how Roughness Grade Numbers convert to Ra numbers. When a material undergoes the process of machining no matter what method it uses it comes out with it with a certain roughness.

These surface treatment methods are to plate a layer of metal film on the surface of the workpiece in order to achieve the required purpose. One of the defining characteristics of this. Use carbide cutting tools.

These units help design engineers as well as. Die casting surface finish is a process designed for altering the surface of a casted metal part by adding removing or reshaping. As you know various acronyms are.

The approach technology for measuring surface finish. Brass Machining Tips. Work with the right tools equipment parameters and conditions can improve the efficiency of high-speed brass cutting.

Roughness Grade Numbers and Ra Measures. 3 Functions of Surface Finish for CNC Machined Parts. Surface Finishing for Machining Guide.

To eliminate the recast layer on the surface machined by multi-pass wire electrical discharge machining WEDM hence improving the surface integrity the present paper. This guide will provide quality information of surface roughness in machining. It is often the final step in the manufacturing process of.

ASME also publishes the B416 Surface Texture Standard which contains definitions and measurement methods for surface finish. This is done through measurements by using a unit. CNC machined surface finishing changes the morphology chemical composition and organizational structure of the.

The surface Finish of a machined part is described using some parameters which are called surface finish units.

Surface Finish Ra And Rz Roughness Specification Upmold

Surface Finish A Complete Guide To Surface Roughness Wayken

Choosing The Right Flange Surface Finish An Overview Of Asme Esf And Fsa Guidelines Enerpac Blog

Understand The Surface Roughness Chart And Make Great Parts

Surface Finish Gauges Testers Comparators Comparison Specimens Rubert Co Ltd

Cnc Milling Machining Design Guidelines

A Guide To Understanding Surface Roughness Measurement Types Roslerblog

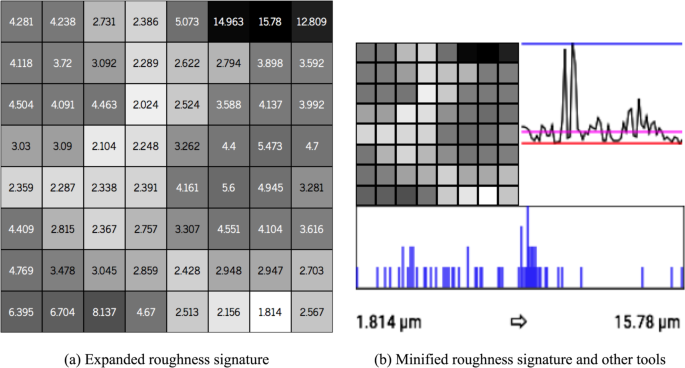

New Method For Evaluating Surface Roughness Parameters Acquired By Laser Scanning Scientific Reports

A Complete Guide To Understand Surface Roughness In Manufacturing Leadrp Rapid Prototyping And Manufacturing Service

Everything You Need To Know About Surface Roughness Aria Manfacturing

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Surface Finish Comparators Selection Guide Types Features Applications Engineering360

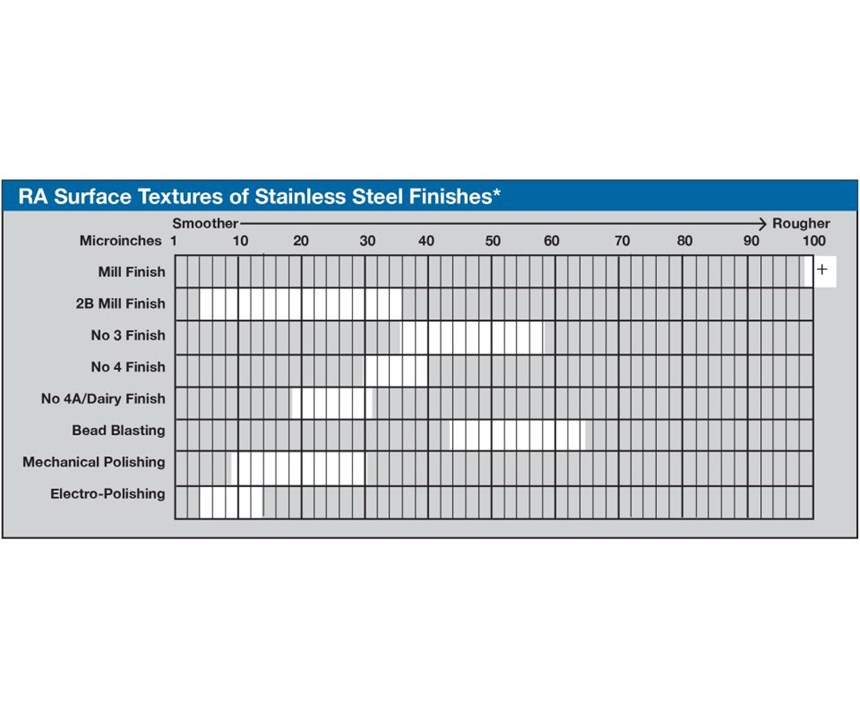

Mastering Sanitary Stainless Steel Finishes Products Finishing

Predicting Surface Roughness In Machining A Review Sciencedirect

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

The Basics Of Metal Surface Finishes

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Predicting Surface Roughness In Machining A Review Sciencedirect